The Company’s plants have cutting-edge conversion and reforming capacities, and produce a wide range of high quality petroleum products. In terms of the engineering properties of their production capacities and the efficiency indicators, the Kazakhstan refineries surpass the average Kazakhstan level, while the European plants of the Company are equal to their competitors and are located close to our key target markets. The Company’s average daily crude production level rose by 1.4% compared with 2018. The Company had lot of work in 2016 to prepare and launch production at fields in Kazakhstan as part of its strategy of accelerated production growth. Special emphasis was placed on fields in Kashagan and Arystan oil field. The Company had lot of work in 2016 to prepare and launch production at fields in Kazakhstan as part of its strategy of accelerated production growth. Special emphasis was placed on fields in Kashagan and Arystan oil field.

Local, Kazakhstani registered companies, such as Ersai and KCOI with operations in Mangystau Oblast, proved their capabilities by manufacturing 75 large pre-assembled pipe-racks and 10 remote instrument enclosures according to international standards. The marine work scope involved the operation of more than 126 vessels, of which 40 were newly constructed vessels or significantly modified to support the project. Meanwhile, KazMorTransFlot operated module carrying vessels in the Caspian Sea. In total, the vessels travelled over 140,000 km between Kazakhstan and other international locations. One of the main legacies of the project is that a new Cargo Transportation Route (CaTRo), was specially built at Prorva near Tengiz, and included a 71 km marine access channel, cargo offloading and storage facilities and a haul road to the Tengiz field where modules are being assembled according to plan.

Since the commencement of FGP-WPMP, TCO has spent over $13.6 billion to purchase Kazakhstani goods and services. Approximately 91 percent of the total project workforce are Kazakhstani citizens. TCO has engaged Kazakhstani entities to participate in FGP-WPMP in engineering, procurement and fabrication services, has pre-screened 2,351 Kazakhstani companies and awarded 1,250 parent contracts to almost 600 to Kazakhstani registered companies.

On November 4th, 2021, FGP-WPMP has safely achieved early oil production from a new metering station. The new metering station is the third of four metering stations, which are connected to their respective clusters of wells, as part of the oil gathering system being built for FGP-WPMP. The 3 existing metering station clusters are already producing over 13 000 tonnes per day or 100,000 barrels crude oil per day of incremental early oil production, which is aimed at keeping existing plants full, alongside improving the ultimate recovery of resources. New full-time positions for the national workforce of Kazakhstan have been created through this latest development.

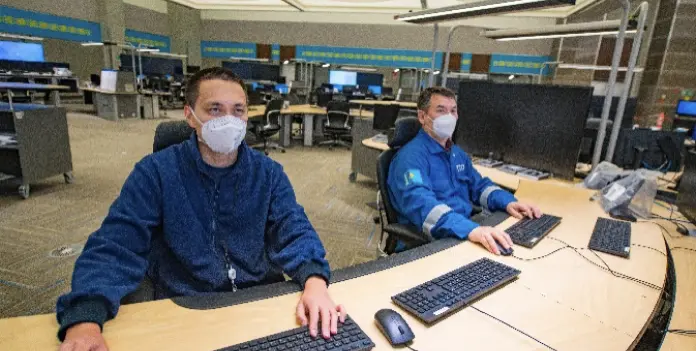

June 3, 2022, at Tengiz was launched an Integrated Operations Control Center (IOCC). This state-of-the art IOCC facility applies the latest digital technologies and is the only facility of its kind in Kazakhstan's oil and gas industry. It will integrate the management of all TCO's production plants into one control center and operating model.

The IOCC is located 20 km away from TCO's production facilities. It also includes a 2200 square meter central control room which is designed to provide Tengiz field operators with the flexibility to make better decisions, improve reliability and optimize production performance. Over 30 Kazakhstani companies and more than 600 employees, contributed to the construction and commissioning of this world class facility. By working on the commissioning of the IOCC the local workforce has also improved their knowledge and skills through comprehensive training and being part of this unique experience.

Kazakhstan Baltic Energy Corporation produces all types petroleum products with high-quality performance and environmental characteristics, including motor fuels, aromatics, liquid paraffin, roofing and insulation materials. We specialize in petroleum refining, with the ability to process 302,000 barrels per day of crude oil from our four U.S. refineries.

As our core value, we have consistently implemented a Production modernization program, including reconstruction and modernization of its production unit, which has improved the quality of products and increased their competition value.

Kazakhstan Baltic Energy CorporationUS is cultivating a portfolio of low-carbon initiatives for itself and its partners, leveraging its competitive strengths in carbon capture, utilization, and storage (CCUS), low-carbon fuels, and various sectors integral to the energy transition

We are committed to protecting the environment and improving our impact on the world around us.

We disclose our environmental, social and governance (ESG) reports, policies and performance to improve our transparency and accountability.

Safety is our top priority, and our training and programs are aimed at encouraging employees to take personal ownership of safety.

Our signature program for charitable contributions has raised millions of dollars for worthy causes in our local communities.